Rivian Ceramic Coating

Welcome, Rivian owners. As Georgia’s trusted automotive protection experts, EZ Auto Spa understands the unique needs of your premium electric truck. Whether you’re cruising through Atlanta’s bustling streets or exploring the scenic routes around Athens, your Rivian represents more than just transportation, it’s a statement of innovation and environmental consciousness that deserves exceptional protection.

Ceramic coating isn’t just another service for your Rivian: it’s essential protection tailored specifically for electric vehicles that face unique challenges. From the advanced paint systems used on these cutting-edge trucks to the specific environmental factors that affect EVs differently than traditional vehicles, professional ceramic coating provides the comprehensive protection your investment demands.

With our extensive experience protecting luxury and premium vehicles throughout North Georgia, we’ve developed specialized techniques that preserve both the striking appearance and long-term value that make Rivian ownership so rewarding. Let’s explore why ceramic coating is particularly beneficial for your electric truck and how professional application delivers results that DIY solutions simply can’t match.

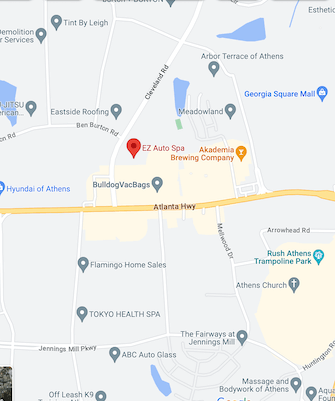

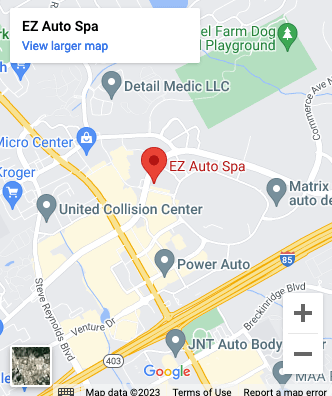

Serving Atlanta + Athens

EZ Auto Spa has two locations conveniently located to serve the Metro Atlanta & Metro Athens area. We serve a wide geographic area and can work with your schedule to make your service happen.

Open Weekdays from

8:30-5:00

Call to ask any question

706-971-7867

Why Rivian Electric Trucks Need Professional Ceramic Coating

Your Rivian faces environmental challenges that traditional vehicles don’t encounter, making professional ceramic coating more critical than you might realize. Electric trucks spend more time parked and charging, often in exposed locations where UV rays, acid rain, and environmental contaminants have extended contact with your paint surface.

Unique Protection Requirements for Electric Vehicles

Rivian’s sophisticated paint system requires specialized protection that accounts for the unique characteristics of electric vehicle ownership. The extended charging times mean your truck sits stationary longer than gas vehicles, increasing exposure to bird droppings, tree sap, and UV damage. Also, Rivian’s aluminum body construction creates specific galvanic corrosion risks when moisture and contaminants interact with dissimilar metals.

The charging infrastructure itself presents protection challenges. Public charging stations are often located in high-traffic areas with increased exposure to road salt, industrial fallout, and urban pollutants. Your Rivian’s paint endures more static exposure to these harmful elements compared to vehicles that spend most of their time in motion or parked in protected residential areas.

Also, electric vehicles like your Rivian generate different heat patterns than internal combustion engines. This affects how environmental contaminants bond with the paint surface, creating unique cleaning and protection requirements that standard waxes and consumer-grade products can’t adequately address.

Benefits of Ceramic Coating for Your Rivian

Ceramic coating transforms your Rivian’s protection profile, delivering benefits that align perfectly with electric vehicle ownership patterns and luxury vehicle expectations.

Long-Term Paint Protection and Durability

Professional ceramic coating creates a semi-permanent barrier that bonds molecularly with your Rivian’s paint, forming protection that lasts years rather than months. This hydrophobic layer repels water, dirt, and contaminants while providing superior UV protection that prevents the oxidation and fading common in vehicles exposed to extended sunlight during charging sessions.

The coating’s self-cleaning properties mean your Rivian stays cleaner longer between washes, reducing the frequency of potentially damaging wash cycles. When contaminants do accumulate, they release more easily during cleaning, minimizing the aggressive scrubbing that can create swirl marks and micro-scratches on your truck’s pristine finish.

Enhanced Resale Value for Premium Electric Vehicles

Rivian trucks represent significant investments, with resale values heavily dependent on cosmetic condition. The electric vehicle market is particularly sensitive to appearance and maintenance history, as buyers view well-maintained EVs as indicators of overall care and battery health.

Ceramic coating preserves the showroom-quality finish that commands top resale prices. Protected Rivians show dramatically less paint degradation, maintaining the deep gloss and color saturation that distinguish well-cared-for vehicles from those with compromised paint systems. Documentation of professional ceramic coating also signals to potential buyers that you’ve invested in proper protection, supporting premium pricing when it’s time to upgrade.

The coating’s durability means your investment continues paying dividends throughout your ownership period, unlike waxes or sealants that require frequent reapplication and offer minimal long-term protection benefits.

Professional vs DIY Ceramic Coating for Rivian Trucks

While DIY ceramic coating products flood the consumer market, the reality is that professional application delivers fundamentally different results for your Rivian. The difference isn’t just in skill, it’s in product quality, preparation standards, and environmental control that determine long-term performance.

Professional-grade ceramic coatings use advanced silicon dioxide formulations unavailable to consumers, creating harder, more durable protection layers. These industrial coatings require specific application temperatures, humidity control, and curing conditions that home garages simply can’t provide. Your Rivian’s complex curves, panel transitions, and charging port areas demand precise technique to ensure complete, uniform coverage.

The preparation process separates professional results from DIY attempts. Proper ceramic coating requires paint correction to remove existing defects, thorough decontamination using specialized clay treatments and chemical strippers, and final surface preparation with alcohol-based cleaners. Consumer products designed for “easy application” compromise on these critical preparation steps, resulting in poor adhesion and premature failure.

Professional installers also understand Rivian-specific considerations: which panels require extra attention, how to protect sensitive electronic components during application, and proper masking techniques for charging ports and sensors. This expertise prevents damage and ensures optimal coverage that DIY applications frequently miss.

Warranty protection represents another crucial difference. Professional ceramic coating comes with multi-year warranties backed by the installer’s reputation and insurance. DIY products offer no such protection, leaving you responsible for any application failures or resulting paint damage.

Ceramic Coating Process for Electric Trucks

Professional ceramic coating for your Rivian follows a meticulous process designed specifically for electric vehicle requirements and premium paint systems. Understanding this process helps you appreciate why professional application delivers superior, longer-lasting results.

The process begins with comprehensive paint assessment using specialized lighting to identify existing defects, contamination levels, and any previous coating or sealant residue. For Rivians, this includes careful inspection of the charging port area, door handles, and other high-touch surfaces that may require additional preparation.

Next comes thorough decontamination using iron-removal chemicals to eliminate brake dust and industrial fallout, followed by clay bar treatment to remove embedded contaminants. Electric vehicles often accumulate different contamination patterns due to their quiet operation and extended parking periods, requiring adjusted decontamination techniques.

Paint correction follows, addressing swirl marks, light scratches, and oxidation through multi-stage polishing. Rivian’s paint system responds well to professional correction when performed by experienced technicians who understand the specific characteristics of modern automotive clear coats.

The coating application itself requires controlled environmental conditions, temperature between 60-80°F with humidity below 50%. The ceramic coating is applied in thin, even layers using specialized applicators, with each panel receiving multiple passes to ensure complete coverage. Charging ports and sensor areas receive careful masking and precision application to avoid interference with electronic components.

Curing occurs in stages, with initial flash curing followed by extended ambient curing lasting several days. During this period, your Rivian must remain dry and protected from contamination while the coating fully bonds with the paint surface.

Choosing the Right Ceramic Coating Service in North Georgia

Selecting the right ceramic coating provider for your Rivian requires careful evaluation of experience, facilities, and commitment to quality results. Not all shops are equipped to handle premium electric vehicles properly.

Atlanta and Athens Service Areas

North Georgia’s climate presents specific challenges for ceramic coating application and longevity. High humidity, intense summer heat, and seasonal pollen require experienced technicians who understand how these factors affect coating performance and durability.

Look for shops with climate-controlled application bays, as Georgia’s humidity can interfere with proper coating curing. The facility should have adequate space to accommodate Rivian’s substantial size while maintaining the controlled environment necessary for professional results.

Experience with electric vehicles is crucial. Your chosen provider should understand EV-specific considerations: protecting charging ports during application, working around sensitive electronic components, and recognizing the different contamination patterns electric vehicles develop.

Certification from major coating manufacturers indicates proper training and access to professional-grade products. Ask about their experience specifically with Rivian trucks, as these vehicles have unique characteristics that generic EV experience might not address.

Warranty terms reveal the provider’s confidence in their work. Professional installations should include multi-year warranties covering coating failure, along with clear guidelines for maintaining warranty coverage through proper care and maintenance.

Cost and Investment Considerations

Ceramic coating represents a significant investment in your Rivian’s protection, but understanding the true cost requires looking beyond the initial price to long-term value and savings.

Professional ceramic coating for a Rivian typically ranges from $1,200 to $2,500, depending on coating tier, paint condition, and package inclusions. Premium coatings with 5-7 year warranties command higher prices but deliver proportionally better protection and longevity.

Compare this investment against the alternatives: quality paint correction and protective film installation often exceed ceramic coating costs while providing less comprehensive protection. Regular waxing services, while cheaper individually, accumulate substantial costs over several years while delivering inferior protection.

The protection value becomes clear when considering Rivian’s premium positioning and resale sensitivity. Paint damage that costs $3,000-5,000 to repair professionally is prevented entirely by ceramic coating that costs a fraction of that amount. Insurance may not cover environmental paint damage, making prevention the only viable protection strategy.

Cost per year reveals the true value proposition. A $2,000 ceramic coating lasting 5 years costs $400 annually, less than many Rivian owners spend on premium car washes in a few months. Factor in reduced washing frequency, eliminated waxing costs, and preserved resale value, and ceramic coating often pays for itself during ownership.

Financing options make professional coating accessible without large upfront payments. Many shops offer payment plans that spread costs over several months, making premium protection affordable for any budget.

Maintenance and Care After Ceramic Coating

Maintaining your ceramic-coated Rivian requires adjusted care routines that maximize coating performance and longevity. Proper maintenance ensures you realize the full benefit of your protection investment.

Washing frequency decreases significantly with ceramic coating, as the hydrophobic surface repels dirt and contaminants more effectively than unprotected paint. Most coated Rivians require washing every 2-3 weeks instead of weekly, reducing both time commitment and potential wash-induced damage.

When washing is necessary, use pH-neutral shampoos specifically designed for ceramic coatings. Avoid aggressive chemicals, waxes, or polishes that can interfere with the coating’s performance. The two-bucket wash method remains essential, but the coating’s slick surface makes dirt removal much easier and safer.

Drying becomes almost effortless with ceramic coating’s water-beading properties. Most water sheets off during rinsing, with remaining droplets easily removed using clean microfiber towels or forced air drying. This eliminates the aggressive towel contact that creates swirl marks on unprotected paint.

Charging station protocols matter for maintaining coating integrity. Park away from high-traffic areas when possible, and address bird droppings or tree sap immediately rather than letting them cure onto the surface during extended charging sessions.

Annual coating maintenance boosts performance and extends durability. Professional maintenance includes thorough decontamination, surface evaluation, and application of coating-compatible sealers that refresh the hydrophobic properties and maintain optimal gloss levels.

Avoid automatic car washes entirely, as their harsh chemicals and abrasive brushes can degrade coating performance over time. Stick to hand washing or touchless washes when professional care isn’t practical.

Explore our posts on Rivian cars – Rivian R1T, Rivian Window Tinting, Rivian Dent Repair, Rivian Ceramic Coating, Rivian Paint Protection Film (PPF), Rivian R2.

Frequently Asked Questions

Why does my Rivian need ceramic coating more than traditional gas vehicles?

Rivian electric trucks spend more time stationary during charging, increasing exposure to UV rays, bird droppings, and environmental contaminants. The aluminum body construction and unique heat patterns also create specific protection challenges that ceramic coating addresses.

How much does ceramic coating cost for a Rivian truck in Atlanta or Athens?

Professional ceramic coating for Rivians typically ranges from $1,200 to $2,500, depending on coating tier and paint condition. This investment often pays for itself through reduced maintenance costs and preserved resale value.

Can I apply ceramic coating to my Rivian myself, or should I go professional?

Professional application is highly recommended for Rivians. Professionals use advanced formulations unavailable to consumers, provide proper paint correction, and understand EV-specific considerations like protecting charging ports and electronic components during application.

How long does ceramic coating last on electric vehicles?

Professional ceramic coating on Rivian trucks typically lasts 5-7 years with proper maintenance. The coating creates a semi-permanent molecular bond with the paint, providing long-term protection that outlasts traditional waxes by years.

What’s the best way to wash my ceramic coated Rivian?

Use pH-neutral shampoos designed for ceramic coatings and follow the two-bucket wash method. Wash every 2-3 weeks instead of weekly, avoid automatic car washes, and address contaminants immediately after charging sessions.

Does ceramic coating improve Rivian resale value?

Yes, ceramic coating significantly preserves resale value by maintaining showroom-quality finish and preventing paint degradation. Electric vehicle buyers particularly value well-maintained appearances as indicators of overall care and proper maintenance history.

Serving Atlanta + Athens

EZ Auto Spa has two locations conveniently located to serve the Metro Atlanta & Metro Athens area. We serve a wide geographic area and can work with your schedule to make your service happen.

Open Weekdays from

8:30-5:00

Call to ask any question