Jeep Ceramic Coating

If you’re a Jeep owner in Georgia, you already know your vehicle is built for adventure. Whether you’re navigating Atlanta traffic, exploring the North Georgia mountains, or tackling weekend trails around Athens, your Jeep deserves protection that matches its rugged capability and distinctive style.

At EZ Auto Spa, we’ve been Georgia’s trusted automotive protection specialists for years, working with hundreds of luxury and premium vehicle owners who demand the best for their investments. Our ceramic coating services are specifically tailored to meet the unique needs of Jeep owners who want to preserve their vehicle’s aggressive good looks while maintaining that legendary durability.

Ceramic coating isn’t just about making your Jeep shine, it’s about creating a protective barrier that stands up to everything Georgia throws at it, from scorching summer heat to unpredictable weather patterns. For Jeep owners who split time between city streets and off-road adventures, professional ceramic coating delivers the kind of comprehensive protection that keeps your vehicle looking showroom-fresh while enhancing its resale value for years to come.

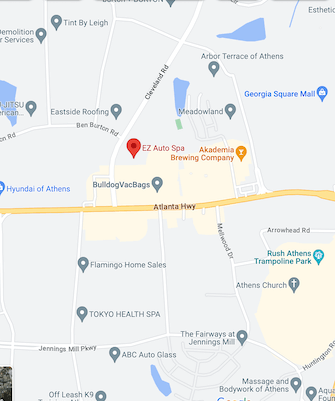

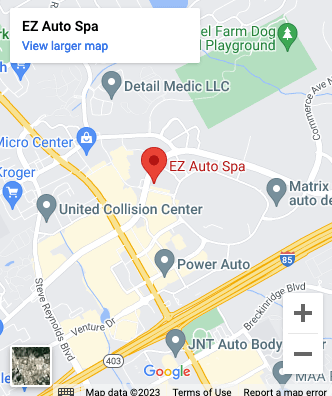

Serving Atlanta + Athens

EZ Auto Spa has two locations conveniently located to serve the Metro Atlanta & Metro Athens area. We serve a wide geographic area and can work with your schedule to make your service happen.

Open Weekdays from

8:30-5:00

Call to ask any question

706-971-7867

Why Jeep Owners Choose Ceramic Coating in Georgia

Georgia’s climate presents unique challenges that make ceramic coating particularly valuable for Jeep owners. Your vehicle faces an aggressive combination of environmental factors that can quickly deteriorate unprotected paint and surfaces.

Protection Against Georgia’s Climate Challenges

Georgia’s intense summer UV rays are relentless, especially when you’re spending time on exposed trails or parked in Atlanta’s concrete jungle. The state’s high humidity levels create the perfect conditions for contaminants to bond with your paint, while sudden thunderstorms and hail can appear without warning. For Jeep owners, these weather patterns are particularly problematic because your vehicle’s upright stance and exposed surfaces catch more environmental punishment than low-profile cars.

Ceramic coating creates a molecular bond with your Jeep’s paint that provides superior UV protection, preventing the fading and oxidation that’s common in Georgia’s climate. The hydrophobic properties mean water, mud, and road grime slide off easily, crucial when you’re transitioning from off-road adventures back to professional settings.

Maintaining Off-Road Performance and Street Appeal

Jeep owners face a unique dilemma: you want a vehicle that looks sharp for daily driving but can handle serious off-road use. Traditional waxes and sealants simply can’t withstand the abuse of trail riding, leaving your paint vulnerable during the adventures that make Jeep ownership so rewarding.

Ceramic coating solves this problem by providing durable protection that doesn’t compromise when you hit the trails. Your Jeep maintains its rugged appeal while being significantly easier to clean after muddy excursions. The coating’s resistance to scratches from brush and debris means your paint stays protected during off-road adventures, while the enhanced gloss ensures you’ll look professional when you return to civilization.

Benefits of Professional Ceramic Coating for Jeeps

Professional ceramic coating offers Jeep owners benefits that go far beyond basic paint protection, addressing the specific challenges that come with owning a versatile adventure vehicle.

Superior Paint Protection and Durability

Jeep’s paint systems are designed for durability, but they still need protection from Georgia’s harsh environmental conditions. Professional ceramic coating creates a permanent molecular bond that becomes part of your vehicle’s surface, providing protection that lasts years rather than months.

The coating’s 9H hardness rating means it can withstand minor scratches from branches, rocks, and other trail debris that would normally mar your paint. Chemical resistance protects against bird droppings, tree sap, and road salt, common threats in Georgia’s diverse driving environments. Unlike traditional protective products that wear away over time, ceramic coating maintains its protective properties through countless wash cycles and weather exposures.

For Jeep owners who frequently wash their vehicles after off-road use, ceramic coating makes maintenance dramatically easier. Dirt, mud, and grime rinse away with minimal effort, reducing the time and harsh chemicals needed to keep your vehicle clean.

Enhanced Resale Value Preservation

Jeeps maintain strong resale values, especially well-maintained models with documented care histories. Professional ceramic coating helps preserve your investment by maintaining your vehicle’s appearance and protecting against the wear patterns that typically reduce resale value.

Potential buyers notice paint condition immediately, and ceramic coating keeps your Jeep looking newer for longer. The enhanced gloss and depth that ceramic coating provides make your vehicle stand out in the used car market, while the protection history demonstrates responsible ownership.

Many Jeep buyers specifically seek vehicles that have been professionally protected because they understand the harsh conditions these vehicles often face. Documentation of ceramic coating service adds credibility to your maintenance claims and can justify premium pricing when it’s time to sell or trade.

Ceramic Coating Process for Jeep Vehicles

Professional ceramic coating application requires specialized knowledge and equipment to achieve lasting results, especially on vehicles like Jeeps that face diverse operating conditions.

Surface Preparation and Paint Correction

The foundation of successful ceramic coating lies in meticulous surface preparation. Your Jeep’s paint must be completely clean and free of defects before coating application begins. This process typically starts with thorough decontamination to remove embedded particles, road tar, and other contaminants that regular washing can’t eliminate.

Paint correction follows, addressing any existing swirl marks, scratches, or oxidation. Jeeps often show wear patterns from outdoor storage or trail use, so this step is crucial for achieving the flawless finish that makes ceramic coating so effective. Professional technicians use specialized compounds and polishing techniques to restore your paint to like-new condition.

The surface must achieve perfect cleanliness before coating application. Any remaining oils, residues, or imperfections will prevent proper bonding and compromise the coating’s performance. Professional shops use multiple cleaning stages and specialized lighting to ensure every surface is ready for coating.

Application and Curing Timeline

Ceramic coating application requires controlled environmental conditions and precise timing. Temperature, humidity, and air circulation must be carefully managed throughout the process to ensure proper curing and bonding.

Application typically takes several hours, as each section must be coated systematically and allowed to cure before moving to adjacent areas. Professional technicians work in small sections, ensuring even coverage and proper bonding before the coating begins to cure.

Curing time varies depending on environmental conditions and the specific ceramic coating product used, but most require 12-24 hours before your Jeep is ready for pickup. During this time, the coating forms its molecular bond with your paint, creating the durable protection that will last for years.

Your Jeep will need special care during the first week after application, avoiding harsh chemicals and excessive moisture while the coating reaches full hardness. Professional shops provide detailed aftercare instructions to ensure optimal results.

Choosing the Right Ceramic Coating Service in North Georgia

Not all ceramic coating services deliver the same results, and choosing the right provider is crucial for Jeep owners who need lasting protection for their investment.

Experience with your specific vehicle type matters significantly. Jeep paint systems, body panel configurations, and typical wear patterns require specialized knowledge for optimal results. Look for shops that regularly work with Jeeps and can demonstrate understanding of your vehicle’s specific needs.

Facility conditions directly impact coating quality. Professional ceramic coating requires controlled environments with proper ventilation, lighting, and temperature control. Shops that cut corners on facility investment often deliver subpar results that won’t provide the long-term protection you’re paying for.

Warranty terms reveal confidence in workmanship. Reputable shops offer comprehensive warranties that cover both materials and labor, with clear terms about what’s covered and for how long. Be wary of services that offer limited warranties or exclude normal use conditions.

Customer testimonials from other Jeep owners provide valuable insights into real-world performance. Look for feedback specifically mentioning off-road use, ease of cleaning, and long-term satisfaction. Photos of completed work can demonstrate the quality and attention to detail you should expect.

Product selection matters for durability and performance. Premium ceramic coating products offer better protection and longevity than budget alternatives. Professional shops should explain their product choices and how different options meet your specific needs and budget.

What to Expect During Your Jeep’s Ceramic Coating Service

Understanding the ceramic coating process helps you prepare appropriately and ensures you get maximum value from your investment.

Your service appointment will begin with a comprehensive vehicle inspection. Technicians will assess your Jeep’s current paint condition, identify any areas requiring special attention, and discuss your expectations for the finished result. This consultation ensures the service plan addresses your vehicle’s specific needs.

The preparation phase typically takes longer than the actual coating application. Your Jeep will undergo thorough washing, decontamination, and paint correction as needed. Don’t be surprised if this phase reveals previously unnoticed paint issues, addressing these problems now prevents them from being locked under the ceramic coating.

During application, your vehicle will remain in the shop’s controlled environment. Most professional shops provide progress updates and may offer photos showing the work in progress. The application process requires patience, as rushing leads to poor results that won’t provide lasting protection.

Pre-delivery inspection ensures every surface has been properly coated and meets quality standards. Professional shops will walk you through the completed work, explaining what’s been done and providing care instructions for optimal longevity.

You’ll receive detailed aftercare instructions covering the first few weeks after application. These guidelines are crucial for allowing the coating to cure properly and achieve maximum durability. Following these instructions carefully ensures you get the full benefit of your investment.

Most shops provide ongoing support and maintenance advice. Building a relationship with your ceramic coating provider helps ensure long-term satisfaction and optimal performance from your protective investment.

Maintaining Your Jeep’s Ceramic Coating

Proper maintenance extends your ceramic coating’s life and ensures continued protection for your Jeep’s paint and surfaces.

Regular washing becomes much easier with ceramic coating, but technique still matters. Use the two-bucket method with pH-neutral car soap to avoid introducing contaminants that could degrade the coating over time. Microfiber wash mitts and towels prevent scratching while effectively removing dirt and grime.

Avoid automatic car washes, especially those using brushes or harsh chemicals. While ceramic coating provides excellent protection, repeated exposure to aggressive cleaning methods can gradually wear down the coating and reduce its effectiveness.

Periodic maintenance treatments help maintain the coating’s hydrophobic properties and gloss. Professional-grade maintenance products are specifically formulated to work with ceramic coatings without causing buildup or interference.

Inspect your coating regularly for any signs of wear or damage, especially after off-road adventures or severe weather events. Early detection of any issues allows for prompt attention before problems become serious.

Professional maintenance services can extend your coating’s life significantly. Annual inspections and maintenance treatments ensure optimal performance and can address any wear patterns before they compromise protection.

Document your maintenance efforts for warranty purposes and future resale value. Keeping records demonstrates responsible ownership and helps maintain your vehicle’s value over time.

Investment and Long-Term Value for Jeep Owners

Ceramic coating represents a significant upfront investment, but the long-term benefits make it cost-effective for serious Jeep owners who want to protect their vehicles.

Compare ceramic coating costs to the cumulative expense of regular waxing, paint touch-ups, and potential paint restoration over several years. Professional ceramic coating typically pays for itself within 2-3 years when you factor in reduced maintenance costs and preserved vehicle value.

Resale value protection often exceeds the coating cost. Well-maintained Jeeps with documented ceramic coating can command premium prices in the used vehicle market, especially among buyers who understand the challenges of maintaining adventure-ready vehicles.

Time savings become significant over the coating’s lifetime. Easier cleaning means less time spent on vehicle maintenance, and the reduced frequency of detailed cleaning saves both time and money over the long term.

Protection against major paint damage can prevent costly repairs. Ceramic coating won’t prevent all damage, but it significantly reduces the likelihood of permanent paint damage from environmental exposure, chemical contamination, or minor impacts.

Peace of mind has value that’s difficult to quantify. Knowing your Jeep is protected against Georgia’s challenging climate lets you enjoy your vehicle without constantly worrying about paint damage or maintenance requirements.

Financing options make professional ceramic coating accessible for more Jeep owners. Many shops offer payment plans that spread the cost over several months, making premium protection affordable for responsible owners who prioritize vehicle care.

Our posts on Jeep cars – Jeep Cherokee, Jeep Commander, Jeep Compass, Jeep Gladiator, Jeep Grand Cherokee, Jeep Grand Wagoneer, Jeep Patriot, Jeep Renegade, Jeep Wagoneer, Jeep Wrangler, Jeep Ceramic Coating, Jeep Dent Repair, Jeep Paint Protection Film (PPF), Jeep Window Tinting.

Frequently Asked Questions About Jeep Ceramic Coating

How long does ceramic coating last on a Jeep in Georgia’s climate?

Professional ceramic coating on Jeeps typically lasts 3-5 years in Georgia’s harsh climate conditions. The molecular bond creates durable protection against UV rays, humidity, and weather extremes that commonly affect vehicles in Atlanta and Athens areas.

Can ceramic coating protect my Jeep during off-road adventures?

Yes, ceramic coating provides excellent protection during off-road use. The 9H hardness rating resists scratches from branches and debris, while hydrophobic properties make mud and dirt removal much easier after trail adventures.

What’s the cost difference between ceramic coating and regular waxing for Jeeps?

While ceramic coating requires a higher upfront investment, it typically pays for itself within 2-3 years by eliminating regular waxing costs, reducing maintenance time, and preserving your Jeep’s resale value significantly.

How soon can I wash my Jeep after ceramic coating application?

You should wait at least one week before washing your Jeep after ceramic coating application. During this curing period, avoid harsh chemicals and excessive moisture to ensure the coating reaches full hardness and bonding.

Does ceramic coating work on Jeep soft tops and plastic trim?

Ceramic coating can be applied to various Jeep surfaces including paint, but specialized formulations are needed for soft tops and plastic trim. Professional installers use different products to protect these materials from UV damage and fading.

Will ceramic coating prevent rock chips on my Jeep’s paint?

Ceramic coating provides some protection against minor impacts but won’t prevent significant rock chips from highway driving or serious off-road use. It excels at protecting against environmental damage, scratches, and chemical contamination rather than major impacts.

Serving Atlanta + Athens

EZ Auto Spa has two locations conveniently located to serve the Metro Atlanta & Metro Athens area. We serve a wide geographic area and can work with your schedule to make your service happen.

Open Weekdays from

8:30-5:00

Call to ask any question