Toyota Mirai Dent Repair, Ceramic Coating & PPF

Your Toyota Mirai represents cutting-edge hydrogen fuel cell technology and sophisticated design that deserves premium protection. As Georgia’s trusted automotive protection specialists, EZ Auto Spa understands the unique needs of Mirai owners who value both innovation and pristine vehicle appearance.

Whether you’re local to Georgia or researching nationwide services, we specialize in three essential protection solutions: Paintless Dent Repair (PDR), Ceramic Coating, and Paint Protection Film (PPF). Each service addresses specific challenges Mirai owners face – from everyday parking lot dings to environmental contaminants that can dull your vehicle’s distinctive finish.

Your Mirai’s aerodynamic surfaces and premium paint finish benefit significantly from professional protection services. Our PDR maintains your vehicle’s factory finish integrity, while ceramic coating provides long-lasting gloss and easy maintenance. PPF offers invisible armor against road debris and stone chips that could compromise your investment. We deliver luxury-level results with practical value that keeps your innovative Toyota looking showroom-fresh.

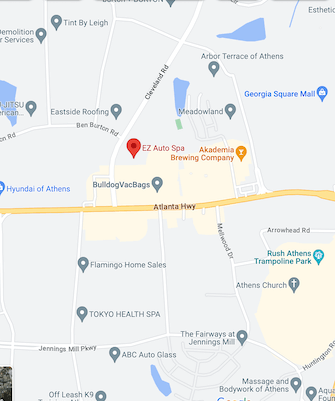

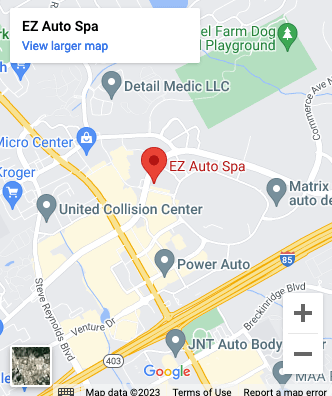

Serving Atlanta + Athens

EZ Auto Spa has two locations conveniently located to serve the Metro Atlanta & Metro Athens area. We serve a wide geographic area and can work with your schedule to make your service happen.

Open Weekdays from

8:30-5:00

Call to ask any question

706-971-7867

Understanding the Toyota Mirai’s Unique Paint and Body Characteristics

Your Toyota Mirai features a lightweight aluminum body construction that requires specialized protection techniques. The hydrogen fuel cell vehicle’s aerodynamic design incorporates thin paint layers over aluminum panels, making traditional dent repair methods potentially damaging to the vehicle’s structural integrity.

Aluminum Body Panel Considerations

Toyota engineers designed the Mirai’s body using high-strength aluminum alloys that respond differently to impact compared to steel vehicles. Your Mirai’s panels maintain their shape memory properties, allowing paintless dent repair technicians to restore original contours without compromising the metal’s molecular structure. This aluminum construction makes your vehicle 40% lighter than comparable steel-bodied cars but requires expert handling during repair processes.

Factory Paint Characteristics

The Mirai’s factory paint system consists of a primer, base coat and clear coat specifically formulated for aluminum substrates. Your vehicle’s paint measures approximately 100-120 microns in total thickness, with the clear coat representing 40-50 microns of that measurement. This thinner paint profile means ceramic coating application requires precise surface preparation to achieve optimal bonding without creating imperfections.

Environmental Vulnerability Factors

Your Mirai’s low coefficient of drag design creates unique airflow patterns that can trap contaminants against specific body areas. The front fascia, door edges and rear spoiler experience concentrated exposure to road debris, UV radiation and chemical pollutants. These vulnerability zones benefit significantly from paint protection film installation, as the thin factory clear coat offers limited defense against stone chips and environmental etching.

Paintless Dent Repair for Toyota Mirai

Paintless dent repair transforms your Mirai’s aluminum panels without compromising the factory finish or hydrogen fuel cell system integrity. This specialized technique preserves the vehicle’s aerodynamic properties while maintaining warranty coverage.

Benefits of PDR for Hydrogen Fuel Cell Vehicles

PDR protects your Mirai’s lightweight aluminum construction from traditional bodywork damage. The process maintains structural integrity while preserving the vehicle’s environmental efficiency ratings and factory specifications.

Common Dent Types and Repair Techniques

Door dings, hail damage, and parking lot impacts respond well to PDR on Mirai panels. Technicians use specialized aluminum-specific tools to massage dents from behind panels without affecting paint layers.

Cost Considerations for Mirai PDR Services

PDR costs 50-70% less than conventional bodywork for your Mirai. Insurance often covers paintless repairs fully, and the process takes 2-4 hours compared to multi-day traditional repairs.

Ceramic Coating Protection for Toyota Mirai

Ceramic coating transforms your Toyota Mirai’s aluminum panels into a hydrophobic shield that enhances the vehicle’s aerodynamic efficiency. This advanced protection system bonds with the factory paint to create a durable barrier against environmental contaminants.

Why Ceramic Coating Is Essential for Mirai Owners

Your Mirai’s lightweight aluminum construction requires specialized protection from road salt and UV radiation that can compromise the factory finish. Ceramic coating prevents oxidation while maintaining the vehicle’s aerodynamic properties and environmental efficiency ratings.

Application Process and Longevity

Professional ceramic coating application involves multi-stage paint correction and precise surface preparation tailored to your Mirai’s aluminum panels. The coating cures for 24-48 hours and provides 2-5 years of protection depending on the specific product grade selected.

Maintenance Requirements for Ceramic-Coated Mirai

Your ceramic-coated Mirai requires pH-neutral washing every 2-3 weeks and annual professional inspections to maintain optimal performance. Avoid automatic car washes and use microfiber towels to preserve the coating’s hydrophobic properties and self-cleaning capabilities.

Paint Protection Film (PPF) Solutions

Paint protection film creates an invisible shield that preserves your Toyota Mirai’s aluminum body while maintaining its aerodynamic efficiency. This thermoplastic urethane film bonds directly to the factory paint system without affecting the vehicle’s hydrogen fuel cell performance or environmental ratings.

High-Impact Areas That Need PPF Coverage

Your Mirai’s front bumper, hood, and side mirrors require comprehensive PPF coverage due to their exposure to road debris and environmental contaminants. The vehicle’s low-profile design makes these areas particularly vulnerable to rock chips and scratches during daily driving conditions.

Self-Healing Properties and Advanced Materials

Modern PPF materials feature self-healing technology that eliminates minor scratches through heat activation from sunlight or warm water. These advanced thermoplastic films maintain optical clarity while providing 8-10 mils of protection thickness specifically engineered for aluminum automotive surfaces.

Installation Process and Professional vs. DIY

Professional PPF installation requires precision cutting and heat-forming techniques that conform to your Mirai’s complex aluminum panel geometry. Expert installers use computer-controlled cutting systems and specialized tools to achieve seamless coverage without compromising the vehicle’s factory finish or aerodynamic properties.

Combining PDR, Ceramic Coating, and PPF Services

Strategic integration of paintless dent repair, ceramic coating, and paint protection film maximizes your Toyota Mirai’s protection while optimizing service efficiency. Professional coordination ensures each treatment complements the others for comprehensive aluminum body preservation.

Optimal Service Sequence and Timing

Complete PDR work first to restore your Mirai’s aluminum panels to factory condition before applying protective coatings. Apply ceramic coating after paint correction, then install PPF over cured ceramic surfaces for maximum adhesion and protection layering.

Long-Term Value and Investment Protection

Combined services protect your Mirai’s resale value by maintaining factory finish integrity and preventing environmental damage accumulation. Professional application provides 5-10 years of comprehensive protection, delivering 3-5x ROI through preserved aesthetics and reduced maintenance costs.

Choosing the Right Service Provider for Your Toyota Mirai

Experience with Toyota Mirai aluminum construction determines service quality for your hydrogen fuel cell vehicle. Expert providers understand the Mirai’s unique lightweight body panels and specialized paint systems that require precise handling techniques.

Certification Requirements for Mirai Services

Automotive Protection Institute (API) certification ensures technicians understand aluminum panel manipulation techniques. Certified Paint Protection Film installers possess manufacturer-specific training for thermoplastic urethane applications. Ceramic Pro certified applicators demonstrate proficiency in multi-stage paint correction processes.

Professional certifications include:

- NAPDRT (National Alliance of Paintless Dent Repair Technicians) membership

- 3M Preferred Installer status for PPF applications

- Ceramic Pro Elite Dealer designation for coating services

- Toyota Technical Education Network completion certificates

Equipment Standards for Aluminum Panel Work

Specialized PDR tools designed for aluminum manipulation prevent metal fatigue and cracking. Climate-controlled spray booths maintain optimal temperature and humidity levels during ceramic coating curing. Computer-controlled cutting systems ensure precise PPF patterns for the Mirai’s aerodynamic surfaces.

Essential equipment specifications:

- LED light arrays providing 5000+ lumens for dent detection

- Pneumatic glue pullers with adjustable tension settings

- Heat guns maintaining 200-250°F temperatures for PPF installation

- Paint thickness gauges measuring coating depths within 0.1 mil accuracy

Warranty Coverage Verification

Comprehensive warranty protection covers both materials and workmanship for Toyota Mirai applications. PDR services typically include 2-year guarantees against paint damage or metal distortion. Ceramic coatings offer 2-5 year warranties depending on product grade and maintenance compliance.

Paint Protection Film installations feature manufacturer warranties ranging from 5-10 years with coverage against yellowing, cracking, and adhesion failure. Insurance claim assistance ensures proper documentation for comprehensive coverage reimbursement.

Quality Assurance Processes

Multi-point inspection protocols verify proper installation techniques and material adhesion quality. Before-and-after documentation includes high-resolution photography showing service completion standards. Customer satisfaction guarantees ensure rework availability if quality standards aren’t met within 30 days.

Professional service providers maintain detailed service records for warranty compliance and future maintenance scheduling. Follow-up inspections at 6-month intervals ensure coating performance and film integrity remain optimal.

Contact our certified Toyota Mirai specialists for personalized service quotes and technical consultations regarding your hydrogen fuel cell vehicle’s protection needs.

Conclusion

Your Toyota Mirai represents cutting-edge hydrogen technology that deserves premium protection to match its innovation. Professional paintless dent repair ceramic coating and PPF services ensure your investment maintains its value while preserving the vehicle’s unique aluminum construction.

Working with certified technicians who understand the Mirai’s specialized requirements makes all the difference in achieving optimal results. These combined protection strategies offer peace of mind knowing your hydrogen fuel cell vehicle will continue performing at its peak for years to come.

Ready to protect your Mirai’s future? Contact EZ Auto Spa today for a personalized consultation and discover how professional automotive protection can enhance your driving experience while safeguarding your investment.

Explore our posts on Toyota cars – Scion, Scion iA, Scion xB, Tesla Roadster, Toyota 4Runner, Toyota 86, Toyota Avalon, Toyota bZ4X, Toyota C-HR, Toyota Camry, Toyota Celica, Toyota Corolla, Toyota Echo, Toyota FJ Cruiser, Toyota GR Supra, Toyota GR86, Toyota Highlander, Toyota Land Cruiser, Toyota Matrix, Toyota Mirai, Toyota MR2 Spyder, Toyota Prius, Toyota RAV4, Toyota Sequoia, Toyota Sienna, Toyota Tacoma, Toyota Tundra, Toyota Venza, Toyota Yaris, Toyota Window Tinting, Toyota Ceramic Coating, Toyota Dent Repair, Toyota Paint Protection Film (PPF).

Frequently Asked Questions

What makes the Toyota Mirai’s aluminum body unique for protection services?

The Toyota Mirai features a lightweight aluminum construction with thin paint layers and high-strength panels. This unique combination requires specialized protection techniques since traditional bodywork methods can damage the aluminum’s integrity. The factory paint system is specifically formulated for aluminum surfaces, making professional expertise essential for services like ceramic coating and paint protection film applications.

How does Paintless Dent Repair work on the Toyota Mirai?

PDR uses specialized tools to massage dents from behind the aluminum panels without affecting the paint or compromising the hydrogen fuel cell system. This technique preserves the Mirai’s aerodynamic properties and warranty coverage while maintaining factory specifications. Common issues like door dings, hail damage, and parking lot impacts respond well to PDR on aluminum surfaces.

What are the benefits of ceramic coating for the Toyota Mirai?

Ceramic coating creates a hydrophobic shield that enhances the Mirai’s aerodynamic efficiency while protecting against environmental contaminants and oxidation. It bonds with the factory paint to form a durable barrier lasting 2-5 years. The coating requires precise surface preparation for aluminum panels and provides long-term protection with proper maintenance using pH-neutral products.

Why is Paint Protection Film recommended for the Toyota Mirai?

PPF creates an invisible shield that preserves the aluminum body while maintaining aerodynamic efficiency and hydrogen fuel cell performance. The thermoplastic urethane film offers 8-10 mils of protection thickness with self-healing technology for minor scratches. High-impact areas like the front bumper, hood, and mirrors are particularly vulnerable and benefit most from comprehensive PPF coverage.

What’s the best order for combining protection services on a Mirai?

The optimal sequence is: first complete PDR to restore aluminum panels to factory condition, then apply ceramic coating, and finally install PPF over the cured ceramic surfaces. This strategic integration maximizes adhesion and creates layered protection, delivering 5-10 years of comprehensive coverage while maintaining the vehicle’s aerodynamic properties and factory finish.

How much does professional protection cost compared to traditional repairs?

PDR is 50-70% less expensive than conventional bodywork and takes only 2-4 hours versus multi-day traditional repairs. The combined protection approach offers a 3-5 times return on investment through preserved aesthetics, reduced maintenance costs, and maintained resale value. Insurance often covers PDR services, making it even more cost-effective for Mirai owners.

What certifications should I look for in a Toyota Mirai service provider?

Look for technicians with Automotive Protection Institute (API) certification and experience with aluminum construction. Quality providers should have specialized PDR tools for aluminum panels, climate-controlled environments for ceramic coating applications, and comprehensive warranties covering both materials and workmanship. Professional organization memberships also indicate expertise in handling specialized paint systems.

Serving Atlanta + Athens

EZ Auto Spa has two locations conveniently located to serve the Metro Atlanta & Metro Athens area. We serve a wide geographic area and can work with your schedule to make your service happen.

Open Weekdays from

8:30-5:00

Call to ask any question