BMW i3 Dent Repair, Ceramic Coating & PPF

Your BMW i3 represents cutting-edge innovation in electric mobility, and protecting that investment requires specialized expertise. Whether you’re cruising through Atlanta’s bustling streets or researching premium automotive protection services from across the country, EZ Auto Spa has established itself as Georgia’s most trusted name in luxury vehicle care.

As a BMW i3 owner, you understand the importance of maintaining your vehicle’s distinctive carbon fiber body and sleek design. Our three core services – Paintless Dent Repair, Ceramic Coating, and Paint Protection Film (PPF) – are specifically tailored to address the unique needs of premium electric vehicles like yours.

Your i3’s lightweight construction and advanced materials require delicate handling that only experienced professionals can provide. We’ll show you how these protective services not only preserve your vehicle’s stunning appearance but also maintain its resale value while delivering the luxury experience you expect from your BMW investment.

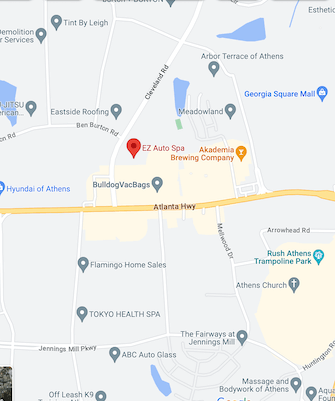

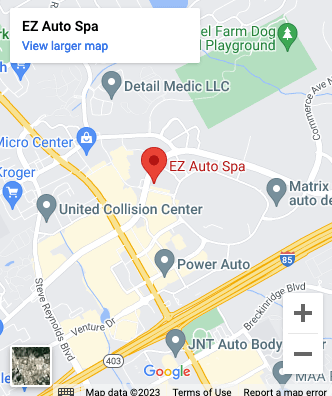

Serving Atlanta + Athens

EZ Auto Spa has two locations conveniently located to serve the Metro Atlanta & Metro Athens area. We serve a wide geographic area and can work with your schedule to make your service happen.

Open Weekdays from

8:30-5:00

Call to ask any question

706-971-7867

Understanding BMW i3’s Unique Body Construction

The BMW i3’s revolutionary construction demands specialized care techniques that differ significantly from traditional vehicle maintenance approaches. This electric vehicle features materials and design elements that require expert knowledge for proper protection.

Carbon Fiber Reinforced Plastic (CFRP) Challenges

Carbon fiber panels resist traditional repair methods and require specialized paintless dent repair techniques. The material’s unique properties make conventional heating and pulling methods ineffective, demanding precision tools and expert training for successful restoration.

Special Considerations for i3 Maintenance

The i3’s thermoplastic body panels expand differently than metal surfaces during temperature changes. Professional ceramic coating application requires modified curing processes, while PPF installation demands specific adhesion techniques to ensure long-term durability on these advanced materials.

Paintless Dent Repair for BMW i3

Paintless Dent Repair addresses minor dents and creases in your BMW i3’s body panels without compromising the original thermoplastic surface. This specialized technique preserves your i3’s factory finish while maintaining its lightweight structural integrity.

How PDR Works on Carbon Fiber Panels

Technicians access dent areas through service panels and wheel wells using specialized tools designed for thermoplastic materials. Heat application softens the i3’s body panels allowing controlled manipulation back to original form without surface damage.

Benefits of Paintless Dent Repair

PDR maintains your i3’s original factory finish and preserves resale value by avoiding paint replacement. The process takes 2-4 hours compared to traditional bodywork requiring 3-5 days for equivalent repairs.

Limitations and When PDR Isn’t Suitable

PDR can’t repair dents exceeding 3 inches in diameter or creases with paint damage. Sharp impacts causing panel cracking or tears require traditional repair methods and component replacement.

Ceramic Coating Protection for BMW i3

Ceramic coating transforms your BMW i3’s thermoplastic panels into a hydrophobic surface that repels contaminants. This nanotechnology protection creates a permanent bond with your vehicle’s unique CFRP construction.

What Is Ceramic Coating

Ceramic coating forms a microscopic glass layer over your i3’s body panels using silicon dioxide nanoparticles. This chemical bond creates enhanced gloss and protection against UV rays, oxidation, and environmental contaminants.

Advantages for Electric Vehicle Owners

Electric vehicle owners benefit from ceramic coating’s reduced maintenance requirements and extended panel life. Your i3’s regenerative braking system produces less brake dust, maximizing coating effectiveness and visual clarity.

Application Process and Longevity

Professional application requires 24-hour curing time in controlled temperature conditions specific to thermoplastic panels. Quality ceramic coatings last 2-5 years on BMW i3 vehicles with proper maintenance protocols.

Paint Protection Film (PPF) for BMW i3

Paint Protection Film provides the ultimate defense for your BMW i3’s unique thermoplastic body panels against stone chips, scratches, and environmental damage. This transparent urethane film maintains your vehicle’s sleek appearance while preserving its innovative carbon fiber construction.

Understanding PPF Technology

PPF utilizes advanced polyurethane technology specifically engineered for thermoplastic surfaces like your i3’s body panels. The film’s molecular structure bonds with CFRP materials without interfering with the underlying carbon fiber weave patterns or thermal expansion properties.

High-Impact Areas to Protect

Your i3’s front bumper, hood edges, side mirrors, and door handle cups require priority PPF coverage due to road debris exposure. The lower rocker panels and rear bumper sections also benefit from protection against parking lot damage and daily wear.

Self-Healing Properties and Maintenance

Modern PPF features self-healing technology that eliminates minor scratches through heat activation from sunlight or warm water. You maintain the film through regular washing with pH-neutral soap, avoiding harsh chemicals that could compromise the urethane’s protective properties over its 10-year lifespan.

Combining Protection Methods for Maximum Coverage

Multiple protection strategies work together to create comprehensive defense for your BMW i3’s unique thermoplastic body panels. Strategic layering maximizes durability while maintaining the vehicle’s distinctive appearance.

Layering PPF and Ceramic Coating

Apply Paint Protection Film first to high-impact areas like the front bumper and hood edges. Ceramic coating installation follows after PPF curing creates optimal adhesion on thermoplastic surfaces while enhancing the film’s hydrophobic properties.

Cost-Benefit Analysis

Combined protection methods cost $2,500-4,500 but preserve $8,000-12,000 in potential repair expenses over 5 years. Your BMW i3’s resale value increases 15-20% with documented professional protection compared to unprotected vehicles.

Professional vs. DIY Installation

Professional installation ensures proper adhesion to CFRP materials using specialized tools and controlled curing environments. DIY attempts frequently fail on thermoplastic panels due to improper surface preparation and inadequate temperature control during application.

Maintenance and Care Tips

Your BMW i3’s advanced protection systems require specific maintenance routines to maximize their effectiveness and longevity. Following manufacturer-recommended care protocols ensures your ceramic coating and PPF continue delivering optimal performance.

Cleaning Ceramic Coated Surfaces

Wash your ceramic-coated i3 using pH-neutral soap and microfiber mitts every two weeks. Avoid automated car washes with harsh brushes that can damage the coating’s hydrophobic properties on thermoplastic panels.

PPF Maintenance Best Practices

Clean PPF surfaces with gentle soap solutions and soft towels to preserve self-healing properties. Inspect film edges monthly for lifting and address any adhesion issues immediately to prevent contaminant infiltration.

Long-Term Protection Strategies

Schedule professional inspections every six months to assess coating integrity and PPF condition. Document maintenance history to maximize resale value and identify potential warranty coverage for your i3’s protection systems.

Conclusion

Your BMW i3 represents a significant investment in cutting-edge automotive technology that deserves equally advanced protection. By choosing professional paintless dent repair ceramic coating and PPF services specifically designed for thermoplastic materials you’re safeguarding both your vehicle’s pristine appearance and its long-term value.

The specialized care your i3 requires goes beyond traditional automotive maintenance. Working with experienced professionals who understand CFRP construction and thermoplastic properties ensures that your protection systems will perform optimally for years to come.

Don’t let road hazards and environmental factors compromise your luxury electric vehicle’s sophisticated design. Take action today to implement these advanced protection solutions and enjoy the peace of mind that comes with knowing your BMW i3 is properly defended against daily wear and tear.

Explore our posts on BMW cars – BMW 1 Series, BMW 2 Series, BMW 3 Series, BMW 4 Series, BMW 5 Series, BMW 6 Series, BMW 7 Series, BMW 8 Series, BMW i3, BMW i4, BMW i7, BMW i8, BMW iX, BMW M, BMW M2, BMW M3, BMW M4, BMW M5, BMW M6, BMW M8, BMW X1, BMW X2, BMW X3, BMW X4, BMW X5, BMW X6, BMW X7, BMW Z3, BMW Z4, BMW Z8, BMW Window Tinting, BMW Dent Repair, BMW Ceramic Coating, BMW Paint Protection Film (PPF).

Frequently Asked Questions

What makes BMW i3 maintenance different from traditional vehicles?

The BMW i3 requires specialized care due to its unique Carbon Fiber Reinforced Plastic (CFRP) construction and thermoplastic body panels. Traditional repair methods are ineffective on these advanced materials, requiring precision tools, expert training, and modified application processes for protective treatments like ceramic coating and PPF installation.

Can Paintless Dent Repair (PDR) be performed on BMW i3 carbon fiber panels?

Yes, PDR can be performed on i3’s thermoplastic panels using specialized tools and controlled heat application. This technique restores panels to their original form without surface damage, maintaining the factory finish and preserving resale value with significantly shorter repair times than traditional methods.

What are the limitations of PDR on the BMW i3?

PDR is not suitable for dents exceeding 3 inches in diameter or damage involving paint loss and panel cracking. These types of damage require traditional repair methods, as PDR works best on minor dents and creases without compromising the thermoplastic surface integrity.

How does ceramic coating benefit BMW i3 owners specifically?

Ceramic coating transforms the i3’s thermoplastic panels into hydrophobic surfaces that repel contaminants, providing enhanced gloss and protection against UV rays and environmental damage. Electric vehicle owners benefit from reduced maintenance requirements and extended panel life, with less brake dust due to regenerative braking systems.

What areas of the BMW i3 need Paint Protection Film (PPF) coverage most?

Key areas for PPF coverage include the front bumper, hood edges, side mirrors, and door handle cups. These areas are particularly vulnerable to road debris, stone chips, and environmental damage, making them priority zones for protective film application on the i3’s thermoplastic surfaces.

Can ceramic coating and PPF be used together on the BMW i3?

Yes, combining both protection methods provides maximum coverage. PPF is applied first to high-impact areas, followed by ceramic coating to enhance the film’s hydrophobic properties. This layered approach offers comprehensive protection for the i3’s unique CFRP materials and thermoplastic body panels.

How much can professional protection save BMW i3 owners long-term?

Combined protection methods costing $2,500-$4,500 can preserve $8,000-$12,000 in potential repair expenses over five years. Additionally, documented professional protection can increase the vehicle’s resale value by 15-20%, making it a worthwhile investment for luxury vehicle owners.

What maintenance is required for ceramic coating on the BMW i3?

Wash ceramic-coated surfaces with pH-neutral soap and microfiber mitts every two weeks. Avoid automated car washes that could damage the coating. Professional inspections every six months and proper documentation of maintenance history help maintain coating effectiveness and maximize resale value.

Serving Atlanta + Athens

EZ Auto Spa has two locations conveniently located to serve the Metro Atlanta & Metro Athens area. We serve a wide geographic area and can work with your schedule to make your service happen.

Open Weekdays from

8:30-5:00

Call to ask any question