Ram 3500 Dent Repair, Ceramic Coating & PPF

Your Ram 3500 deserves protection that matches its rugged capability and impressive presence. Whether you’re hauling heavy loads across Georgia’s diverse terrain or showcasing your truck’s commanding style, maintaining its pristine appearance requires specialized care that standard detailing simply can’t provide.

At EZ Auto Spa, we understand that Ram 3500 owners demand durability and performance from every aspect of their vehicle. That’s why we’ve become Georgia’s trusted experts in advanced automotive protection services, serving local customers and truck enthusiasts researching quality care nationwide. Our three signature services – Paintless Dent Repair, Ceramic Coating, and Paint Protection Film (PPF) – are specifically designed to address the unique challenges your heavy-duty truck faces.

These aren’t just cosmetic upgrades; they’re practical investments that preserve your Ram 3500’s value while delivering a luxury experience. From eliminating work-site dings to creating an invisible shield against road debris, our services ensure your truck maintains its commanding presence mile after mile.

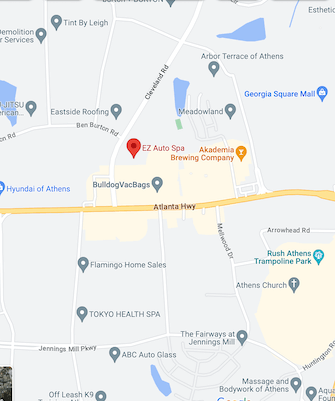

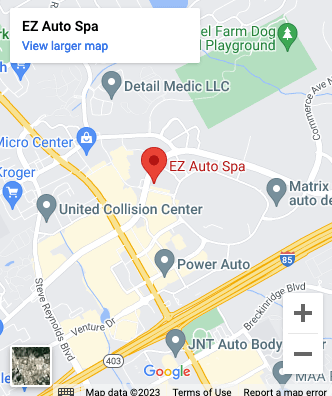

Serving Atlanta + Athens

EZ Auto Spa has two locations conveniently located to serve the Metro Atlanta & Metro Athens area. We serve a wide geographic area and can work with your schedule to make your service happen.

Open Weekdays from

8:30-5:00

Call to ask any question

706-971-7867

Understanding Ram 3500 Paint Protection Needs

Your Ram 3500 faces unique challenges that standard protection methods can’t adequately address. Heavy-duty work environments expose your truck’s paint to construction debris, gravel impacts, and harsh chemical exposure that lighter vehicles rarely encounter.

Work Environment Hazards

Construction sites present multiple paint threats including:

- Flying concrete chips from demolition work

- Metal shavings from welding operations

- Chemical splashes from industrial cleaning agents

- Gravel kickback on unpaved job sites

Towing and Hauling Impacts

Your truck’s substantial towing capacity creates specific paint vulnerabilities. Trailer connections generate metal-on-metal contact points that scratch your tailgate and bumper surfaces. Heavy payload positioning often results in cargo contact marks along your bed rails and sidewalls.

Highway Exposure Factors

Interstate driving at highway speeds amplifies stone chip damage on your Ram 3500’s front end. The truck’s large surface area and upright stance catch more road debris than smaller vehicles. Salt exposure during winter months accelerates paint oxidation on your wheel wells and lower panels.

Value Preservation Requirements

Your Ram 3500 represents a significant investment requiring protection strategies that match its premium status. Factory paint deterioration directly impacts your truck’s resale value and professional appearance. Professional-grade protection maintains your vehicle’s commanding presence while preserving its market position.

What Is Paintless Dent Repair for Ram 3500 Trucks

Paintless Dent Repair (PDR) restores your Ram 3500’s metal panels without traditional body filler or paint. This precision technique removes dents while preserving your truck’s original factory finish.

How PDR Works on Heavy-Duty Vehicles

Specialized technicians access dents from behind your Ram 3500’s panels using custom tools. Metal manipulation techniques restore the original contour without damaging protective coatings or paint integrity on heavy-gauge steel.

Benefits of PDR Over Traditional Bodywork

PDR maintains your Ram 3500’s factory paint warranty and original finish quality. You save 60-80% compared to conventional bodywork while avoiding color-matching issues and maintaining authentic manufacturer specifications.

Ceramic Coating for Ram 3500 Durability

Ceramic coating transforms your Ram 3500’s paint into a hardened protective barrier that withstands industrial-grade punishment. This advanced nanotechnology creates a permanent bond with your truck’s factory finish.

What Ceramic Coating Offers Your Ram 3500

Your Ram 3500 receives 9H hardness protection against scratches, chemical stains, and UV damage. Ceramic coating repels dirt, mud, and road salt while creating a hydrophobic surface that makes washing effortless and maintains your truck’s commanding appearance.

Application Process and Longevity

Professional ceramic coating application takes 2-3 days with paint correction and curing time. Your Ram 3500’s ceramic coating lasts 5-7 years with proper maintenance, providing long-term protection that outperforms traditional wax applications by decades.

Paint Protection Film (PPF) for Maximum Defense

Paint Protection Film delivers unmatched physical protection for your Ram 3500’s paint surface against the most aggressive threats. This transparent urethane film creates an invisible shield that absorbs impacts and prevents permanent damage.

Why Ram 3500 Owners Choose PPF

Your heavy-duty truck faces constant threats from construction debris, highway gravel, and industrial environments. PPF provides self-healing technology that eliminates minor scratches automatically through heat activation, maintaining your truck’s pristine appearance despite demanding work conditions.

High-Impact Areas to Protect

| Protected Area | Threat Level | Damage Prevention |

|---|---|---|

| Front bumper | Extreme | Rock chips, gravel impact |

| Hood leading edge | High | Stone damage, debris |

| Fender wells | High | Tire kickback, road salt |

| Door edges | Medium | Parking lot dings, cargo contact |

| Mirror caps | Medium | Branch scratches, weather exposure |

PPF installation on these critical zones prevents 95% of paint damage that typically occurs during the first three years of ownership. Your Ram 3500’s value retention increases significantly when protected areas maintain factory-fresh appearance despite exposure to harsh working environments.

Combining All Three Services for Complete Protection

You maximize your Ram 3500’s protection when you combine paintless dent repair, ceramic coating, and paint protection film into a comprehensive defense system. This integrated approach delivers superior results compared to individual services.

Cost-Effective Protection Packages

Bundling all three services reduces your total investment by 20-25% compared to individual applications. You save on preparation time since paint correction occurs once for both ceramic coating and PPF installation.

Maintenance Tips for Long-Lasting Results

Wash your Ram 3500 every 2 weeks using pH-neutral soap and microfiber towels. Inspect PPF edges monthly for lifting and schedule ceramic coating maintenance every 12 months for optimal performance.

Choosing the Right Service Provider

Selecting a qualified service provider for Ram 3500 protection requires evaluating specific heavy-duty truck expertise and advanced equipment capabilities. Professional automotive protection shops must demonstrate proven experience with commercial-grade vehicles and possess specialized tools designed for large truck applications.

Certification Requirements

ASE Certification ensures technicians maintain industry-standard knowledge for paintless dent repair techniques on heavy-duty vehicles. 3M Authorized Installers provide warranty-backed ceramic coating and PPF applications using manufacturer-approved products. I-CAR Training validates proper collision repair procedures specific to Ram truck construction methods.

| Certification Type | Validation Period | Ram 3500 Relevance |

|---|---|---|

| ASE Master Technician | 5 years | Heavy-duty PDR expertise |

| 3M Preferred Installer | Annual renewal | Premium coating warranty |

| XPEL Certified | 2 years | PPF installation precision |

Equipment Standards

Professional-grade paint correction machines with variable speed controls handle Ram 3500’s robust paint systems effectively. Dual-action polishers remove industrial contamination without creating swirl marks on large surface areas. Paint thickness gauges measure coating depth across different panel materials found in heavy-duty truck construction.

Clean room environments eliminate dust contamination during ceramic coating application. Temperature-controlled bays maintain optimal curing conditions for PPF installation on oversized panels.

Experience Verification

Request documentation of completed Ram 3500 projects showing before-and-after results from similar work environments. Portfolio examples should include construction vehicles, towing rigs, and commercial fleet applications demonstrating real-world protection performance.

Customer references from other heavy-duty truck owners provide insight into service quality and long-term satisfaction rates. Warranty coverage extending 5-7 years indicates confidence in workmanship and material durability.

Contact EZ Auto Spa’s shop manager for personalized Ram 3500 protection quotes and detailed service consultations tailored to your specific truck usage requirements.

Conclusion

Your Ram 3500 represents a significant investment that deserves professional-grade protection. Whether you choose PDR for dent restoration ceramic coating for chemical resistance or PPF for impact protection you’re making a smart decision that preserves your truck’s value and appearance.

EZ Auto Spa’s comprehensive approach ensures your heavy-duty truck receives the specialized care it demands. With certified technicians advanced equipment and proven results you can trust your Ram 3500 to maintain its commanding presence for years to come.

Don’t let industrial environments and highway hazards diminish your truck’s value. Contact EZ Auto Spa today for a personalized consultation and discover how proper protection can keep your Ram 3500 looking and performing at its absolute best.

Explore our posts on Ram cars – Ram 1500, Ram 2500, Ram 3500, Ram C V, Ram Dakota, Ram ProMaster, Ram Ceramic Coating, Ram Paint Protection Film (PPF), Ram Dent Repair, Ram Window Tinting.

Frequently Asked Questions

What makes the Ram 3500 require specialized automotive protection?

The Ram 3500 faces unique challenges due to heavy-duty work environments, including flying concrete chips, metal shavings, chemical splashes, gravel kickback, and salt exposure. Standard protection methods are insufficient for these industrial-grade hazards. Professional-grade protection is essential to preserve the truck’s value and maintain its commanding presence in demanding work conditions.

How does Paintless Dent Repair (PDR) work on Ram 3500 trucks?

PDR restores metal panels without traditional body filler or paint by accessing dents from behind panels using specialized tools. Technicians manipulate the metal back to its original shape while preserving the factory finish. This process maintains the factory paint warranty, costs 60-80% less than traditional bodywork, and avoids color-matching issues.

What are the benefits of ceramic coating for Ram 3500 trucks?

Ceramic coating transforms paint into a hardened protective barrier with 9H hardness protection against scratches, chemical stains, and UV damage. It repels dirt, mud, and road salt while lasting 5-7 years with proper maintenance. The nanotechnology provides industrial-grade protection that significantly outpaces traditional wax applications for heavy-duty work environments.

How does Paint Protection Film (PPF) protect my Ram 3500?

PPF creates an invisible urethane shield that absorbs impacts and prevents permanent damage from construction debris, highway gravel, and industrial hazards. The self-healing technology automatically eliminates minor scratches through heat activation. PPF can prevent 95% of paint damage during the first three years, significantly enhancing value retention.

Which areas of my Ram 3500 need PPF protection most?

High-impact areas include the front bumper, hood leading edge, fender wells, door edges, and mirror caps. These zones face the greatest exposure to road debris, construction materials, and loading/unloading damage. Protecting these critical areas provides maximum defense against the most common sources of paint damage on heavy-duty trucks.

Can I combine PDR, ceramic coating, and PPF services?

Yes, combining all three services creates a comprehensive protection system that maximizes your Ram 3500’s defense. Bundled protection packages can reduce total investment by 20-25% compared to individual services. This integrated approach provides superior results and long-term value for heavy-duty truck owners.

How do I maintain my Ram 3500’s protection services?

Maintain your truck with bi-weekly washes using pH-neutral soap, monthly PPF edge inspections, and annual ceramic coating maintenance. Avoid automatic car washes with harsh chemicals. Regular maintenance ensures optimal performance and extends the life of your protection investment, keeping your Ram 3500 looking pristine.

What certifications should I look for in a service provider?

Look for ASE Certification for PDR work, 3M Authorized Installer status for ceramic coating and PPF, and I-CAR Training for collision repair expertise. These certifications ensure your service provider has the specialized knowledge and training required for professional-grade Ram 3500 protection services.

How long does the ceramic coating application process take?

The ceramic coating application takes 2-3 days, including paint correction and proper curing time. This timeline ensures optimal bonding and maximum protection performance. Professional application in controlled environments is crucial for achieving the full benefits of ceramic coating technology on heavy-duty trucks.

Is professional protection worth the investment for my Ram 3500?

Yes, professional protection preserves your truck’s value, maintains its appearance in harsh work environments, and prevents costly paint repairs. The investment in PDR, ceramic coating, and PPF pays for itself through enhanced resale value, reduced maintenance costs, and extended paint life in demanding industrial conditions.

Serving Atlanta + Athens

EZ Auto Spa has two locations conveniently located to serve the Metro Atlanta & Metro Athens area. We serve a wide geographic area and can work with your schedule to make your service happen.

Open Weekdays from

8:30-5:00

Call to ask any question