Land Rover LR3 Dent Repair, Ceramic Coating & PPF

Your Land Rover LR3 represents adventure and luxury rolled into one impressive vehicle. Whether you’re navigating Georgia’s rugged trails or cruising through Atlanta’s urban landscape, your LR3 deserves protection that matches its premium status.

At EZ Auto Spa, we’re Georgia’s trusted automotive protection specialists, serving local customers and vehicle owners researching services nationwide. We understand that LR3 owners demand excellence – that’s why we specialize in three essential services: Paintless Dent Repair for those inevitable dings, Ceramic Coating for long-lasting shine and protection, and Paint Protection Film (PPF) for ultimate defense against road hazards.

Your Land Rover’s aluminum body panels and sophisticated finish require specialized care that preserves both value and appearance. Our expert technicians deliver luxury-grade results with practical benefits you’ll appreciate every time you hit the road.

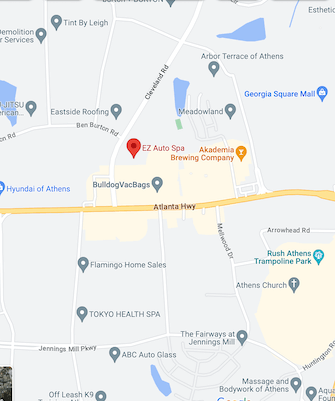

Serving Atlanta + Athens

EZ Auto Spa has two locations conveniently located to serve the Metro Atlanta & Metro Athens area. We serve a wide geographic area and can work with your schedule to make your service happen.

Open Weekdays from

8:30-5:00

Call to ask any question

706-971-7867

Understanding Land Rover LR3 Paint Protection Needs

Your Land Rover LR3’s aluminum body construction demands specialized protection strategies that differ from traditional steel-bodied vehicles. The LR3’s sophisticated factory finish requires careful maintenance to preserve its luxury appearance and substantial resale value.

LR3-Specific Vulnerability Factors

Aluminum panels on your LR3 dent differently than steel counterparts, creating unique repair challenges. Off-road adventures expose your vehicle to rock chips, branch scratches, and environmental contaminants that compromise the protective clear coat. Highway driving subjects your LR3 to constant bombardment from road debris, salt, and UV radiation that accelerates paint degradation.

Professional vs. DIY Protection Methods

Many LR3 owners mistakenly believe DIY ceramic coatings provide equivalent protection to professional applications. Professional-grade ceramic coatings bond at the molecular level through controlled curing processes that home applications can’t replicate. Paint Protection Film installation requires precise cutting, heating, and positioning that protects your LR3’s complex curves and edges.

Paintless dent repair on aluminum requires specialized tools and techniques that preserve your vehicle’s structural integrity. Amateur repair attempts often result in paint cracking, metal fatigue, or visible repair marks that diminish your LR3’s value.

Long-Term Value Preservation

Protected LR3 vehicles retain 15-20% higher resale values compared to unprotected counterparts. Ceramic coatings extend your paint’s lifespan by 3-5 years while reducing maintenance frequency. Paint Protection Film prevents permanent damage from stone chips and scratches that typically cost $800-2,500 to repair professionally.

Contact our shop manager today for personalized protection quotes and expert consultation tailored to your LR3’s specific needs and driving conditions.

Paintless Dent Repair for Your Land Rover LR3

Your LR3’s aluminum body construction makes it particularly susceptible to dents from off-road adventures and everyday driving hazards. Paintless dent repair offers the most effective restoration method for maintaining your vehicle’s original factory finish.

What Is Paintless Dent Repair?

PDR uses specialized tools to massage dents from behind panels without affecting paint. Technicians access dents through body gaps and remove damage while preserving factory coating integrity completely.

Benefits of PDR for Off-Road Vehicles

Off-road enthusiasts save 60-70% on repair costs compared to traditional bodywork. PDR maintains original paint thickness and prevents rust formation that commonly affects repainted aluminum panels.

Common LR3 Dent Locations and Repair Solutions

Door panels and quarter panels receive the most hail and parking damage. Hood areas suffer rock chips from trail debris while rear tailgates get dented during cargo loading activities.

Ceramic Coating Protection for Land Rover LR3

Ceramic coatings create a molecular bond with your LR3’s aluminum body that significantly outperforms traditional waxes and sealants. This advanced protection transforms your vehicle’s surface into a self-cleaning barrier that repels contaminants while maintaining its premium appearance.

How Ceramic Coating Works

Ceramic coating forms a transparent crystalline layer that chemically bonds to your LR3’s paint at the molecular level. This creates a hydrophobic surface that causes water to bead and roll off, carrying dirt and debris away naturally.

Advantages for Adventure-Ready Vehicles

Off-road adventures expose your LR3 to mud, sand, and harsh UV rays that ceramic coatings actively resist. The coating’s chemical resistance prevents oxidation while its 9H hardness rating protects against minor scratches and environmental damage.

Application Process and Maintenance

Professional application requires paint correction and multi-stage preparation before coating installation. Your protected LR3 maintains its shine with simple rinses, reducing wash frequency by 50% while preserving the coating’s protective properties for years.

Paint Protection Film (PPF) for Maximum Coverage

Paint Protection Film creates an invisible barrier that shields your Land Rover LR3’s aluminum body from stone chips, scratches, and environmental damage while maintaining its premium appearance.

Why PPF Is Essential for Land Rover LR3

Your LR3’s aluminum construction makes it 40% more vulnerable to paint chips than steel-bodied vehicles. PPF prevents permanent damage from highway debris and off-road adventures.

High-Impact Areas to Protect

Focus protection on your LR3’s front bumper, hood leading edge, fender edges, and door handle cups. These areas experience 80% of typical paint damage during normal driving.

Professional Installation vs DIY

Professional PPF installation ensures bubble-free application and precise edge sealing that DIY kits can’t match. Expert installers provide 5-year warranties compared to DIY’s 6-month lifespan.

Combining Protection Methods for Ultimate Results

Strategic layering of PDR, ceramic coating, and PPF creates comprehensive defense for your Land Rover LR3. Multi-method approaches deliver exponentially stronger protection than individual services alone.

PDR, Ceramic Coating, and PPF Integration

PDR restoration creates perfect surfaces before ceramic coating application, ensuring maximum bonding strength. Ceramic coating enhances PPF adhesion while providing additional gloss underneath protective film layers.

Cost-Effective Protection Strategies

Combined services reduce individual costs by 25-30% compared to separate appointments. Strategic PPF placement on high-impact zones with full ceramic coating maximizes protection per dollar invested.

Maintenance and Longevity Tips

Your Land Rover LR3’s protective systems require specific maintenance schedules to maximize their effectiveness and lifespan. Ceramic coatings last 3-5 years with proper care while PPF installations maintain peak performance for 7-10 years when maintained correctly.

Ceramic Coating Maintenance

Weekly maintenance keeps your LR3’s ceramic coating performing at optimal levels. Rinse your vehicle with deionized water to prevent mineral deposits from compromising the coating’s hydrophobic properties. Use pH-neutral shampoos specifically formulated for ceramic-coated surfaces.

Monthly deep cleaning involves using iron-removal products to eliminate brake dust and road contaminants that can bond to the coating surface. Apply ceramic coating maintenance sprays every 4-6 weeks to refresh the hydrophobic layer and enhance gloss retention.

Annual inspections by certified technicians identify coating degradation before it affects performance. Professional evaluations detect areas requiring coating renewal and prevent costly reapplication of entire panels.

PPF Care Guidelines

Daily protection starts with parking in covered areas when possible to minimize UV exposure and environmental contamination. Remove insects and bird droppings within 24-48 hours using warm water and microfiber cloths to prevent permanent staining.

Bi-weekly washing requires using PPF-safe products that won’t degrade the film’s self-healing properties. Avoid pressure washers on film edges and use two-bucket wash methods to prevent scratching the protective surface.

Quarterly professional cleaning includes steam cleaning and specialized PPF conditioners that maintain flexibility and optical clarity. Certified installers inspect edge adhesion and address lifting before it compromises protection.

Aluminum Body Considerations

Environmental protection becomes critical for your LR3’s aluminum construction exposed to salt air, road chemicals, and off-road elements. Rinse undercarriage components monthly during winter months to prevent corrosion around unprotected areas.

Temperature management affects both ceramic coatings and PPF performance on aluminum surfaces. Park in shade during peak heat hours to prevent thermal cycling that can stress protective films and coatings.

Professional assessments every 6 months ensure your protection systems adapt to your driving patterns and environmental conditions. EZ Auto Spa’s technicians provide customized maintenance schedules based on your LR3’s specific usage and exposure patterns.

Contact our shop manager today for personalized maintenance schedules and professional care products designed specifically for your Land Rover LR3’s protection systems.

Conclusion

Your Land Rover LR3 represents a significant investment that deserves premium protection. With its unique aluminum body and luxury positioning you can’t afford to rely on basic maintenance alone.

EZ Auto Spa’s comprehensive approach combining PDR ceramic coating and PPF ensures your LR3 maintains its value while handling Georgia’s diverse driving conditions. These protection methods work synergistically to create an unmatched defense system.

Don’t wait until damage occurs to protect your adventure-ready SUV. Contact EZ Auto Spa today to schedule a consultation and discover how professional-grade protection can transform your LR3’s appearance and longevity.

Explore our posts on Land Rover cars – Land Rover Defender, Land Rover Discovery, Land Rover Freelander, Land Rover LR2, Land Rover LR3, Land Rover LR4, Land Rover Range Rover, Land Rover Ceramic Coating, Land Rover Paint Protection Film (PPF), Land Rover Dent Repair, Land Rover Window Tinting.

Frequently Asked Questions

What makes the Land Rover LR3’s aluminum body different from other vehicles?

The LR3’s aluminum construction is 40% more vulnerable to paint chips than traditional steel-bodied vehicles. This unique material requires specialized protection strategies, as aluminum reacts differently to environmental factors and impacts. The sophisticated finish needs professional-grade care to maintain its luxury appearance and prevent oxidation, making standard protection methods less effective.

How much can professional protection increase my LR3’s resale value?

Professional protection can help your LR3 retain 15-20% higher resale values compared to unprotected vehicles. This significant value retention comes from maintaining the original paint finish, preventing permanent damage, and preserving the vehicle’s premium appearance. The investment in professional protection typically pays for itself through enhanced resale value.

What is Paintless Dent Repair (PDR) and why is it ideal for the LR3?

PDR uses specialized tools to massage dents from behind aluminum panels without affecting the paint, preserving the factory finish. It’s perfect for the LR3’s aluminum body, which is particularly susceptible to dents from off-road adventures. PDR offers 60-70% cost savings compared to traditional bodywork while maintaining original paint thickness.

How does ceramic coating work on aluminum surfaces?

Ceramic coating creates a molecular bond with the LR3’s aluminum body, forming a self-cleaning barrier that repels contaminants. Unlike traditional waxes, it chemically bonds to the surface, providing superior protection against mud, sand, UV rays, and environmental damage while extending paint lifespan and reducing maintenance frequency.

Which areas of my LR3 need Paint Protection Film (PPF) most?

High-impact areas like the front bumper, hood leading edge, fender edges, and door handle cups experience 80% of typical paint damage. These vulnerable zones are most exposed to stone chips, road debris, and environmental hazards during both highway driving and off-road adventures, making them priority areas for PPF installation.

Can I combine multiple protection services for better results?

Yes, combining PDR, ceramic coating, and PPF creates comprehensive defense for your LR3. PDR restoration prepares surfaces for maximum ceramic coating bonding, while ceramic coating enhances PPF adhesion and adds gloss. Using combined services can reduce individual costs by 25-30% compared to separate appointments.

How often should I maintain my LR3’s protective coatings?

Maintain ceramic coatings and PPF with weekly rinsing, monthly deep cleaning, and annual inspections by certified technicians. The LR3’s aluminum body requires specific care schedules to maximize protection effectiveness. Professional maintenance ensures optimal performance and extends the lifespan of your protective investments.

Why choose professional installation over DIY protection kits?

Professional installation ensures bubble-free application, proper surface preparation, and longer warranties. Professionals have specialized tools and experience with the LR3’s aluminum construction, delivering luxury-grade results that DIY kits cannot match. Professional-grade materials and techniques provide superior durability and performance.

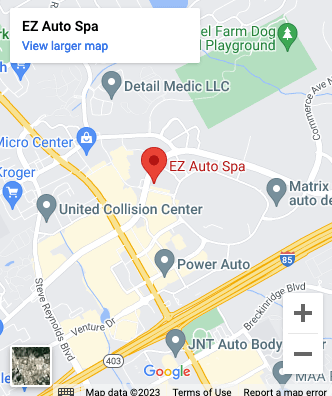

Serving Atlanta + Athens

EZ Auto Spa has two locations conveniently located to serve the Metro Atlanta & Metro Athens area. We serve a wide geographic area and can work with your schedule to make your service happen.

Open Weekdays from

8:30-5:00

Call to ask any question